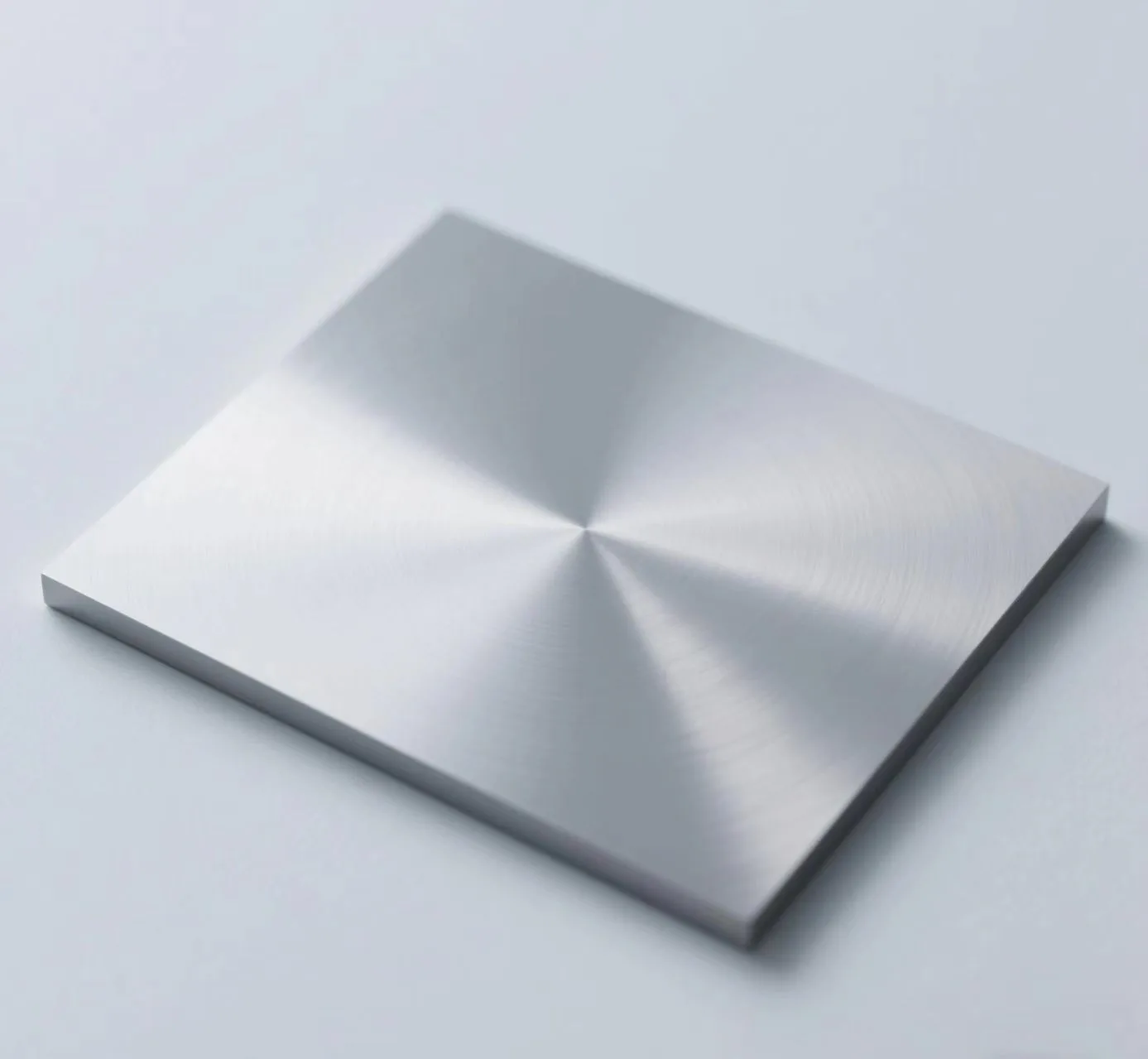

What Are Superconducting Niobium Sheets?

Superconducting niobium sheets are ultra-pure, high-performance metal plates designed for radiofrequency (RF) superconducting accelerators—the machines driving breakthroughs in particle physics and cancer treatment. Governed by standards like YS/T 1638-2023, these sheets are categorized by their Residual Resistance Ratio (RRR)—a measure of electrical purity critical for superconductivity. Imagine them as the “silent engines” behind discoveries like the Higgs boson or proton therapy for tumors.

Why Do RRR Values Matter?

Your ability to push scientific boundaries hinges on niobium’s purity. The higher the RRR, the fewer impurities disrupt electron flow. For example:

- RRR40: Used in basic applications, with 95%+ recrystallization.

- RRR300: Near-perfect purity for cutting-edge accelerators, with grain sizes of 4–6级 (ISO 643).

Even microscopic defects (e.g., surface scratches >15 µm) can sabotage performance—hence strict standards.

How Are Superconducting Niobium Sheets Made?

The process is a dance of precision:

- Purification: Niobium ore is refined to remove impurities like carbon (≤0.01%) and oxygen (≤0.03%).

- Shaping: Rolled into sheets (0.1–6.0 mm thick) under controlled conditions.

- Quality Checks:

- Mechanical Tests: Tensile strength up to 520 MPa (cold-worked state).

- Surface Perfection: Roughness <1.6 µm (Ra) to minimize energy loss.

- Microstructure: Grain uniformity ensures stable superconductivity.

Where Do These Sheets Make an Impact?

- Particle Accelerators: CERN’s Large Hadron Collider relies on niobium cavities to propel particles at near-light speed.

- Medical Imaging: MRI machines use superconducting coils for sharper scans.

- Quantum Computing: Emerging tech for ultra-efficient qubits (Learn more from IBM Research)