In-Depth Advantages of Tantalum Targets in Semiconductor Manufacturing

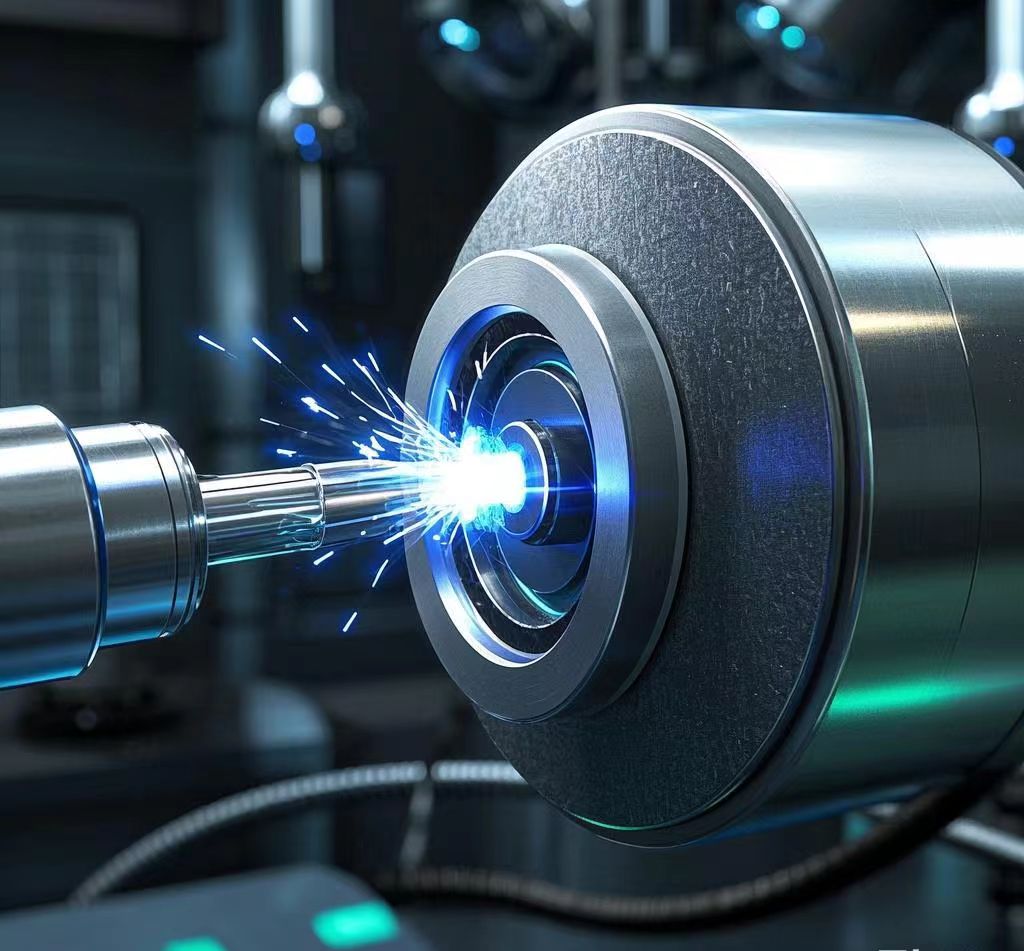

Tantalum targets are indispensable in advanced semiconductor fabrication, particularly for depositing thin films in physical vapor deposition (PVD) processes. Their unique properties address critical challenges in chip miniaturization, performance, and reliability. Below is a detailed breakdown of their key advantages:

1. Ultra-High Purity (≥99.995%)

- Why It Matters: Semiconductor manufacturing demands near-perfect material purity. Even trace impurities like oxygen (<50 ppm), carbon (<10 ppm), or iron can introduce defects, leading to chip failures or reduced performance.

- Impact:

- Defect-Free Films: High-purity tantalum ensures uniform deposition, critical for nanoscale transistors and interconnects.

- Enhanced Yield: Reduces wafer scrap rates in cutting-edge nodes (e.g., 3nm, 2nm).

- Industry Standard: Compliant with SEMI and ASTM specifications for sputtering targets.

2. Extreme Thermal and Plasma Resistance

- Melting Point: ~3,017°C, one of the highest among metals.

- Performance Under Stress:

- PVD/Plasma Stability: Withstands high-energy ion bombardment and temperatures exceeding 1,500°C without warping or cracking.

- Longevity: Outlasts alternatives like titanium or tungsten in continuous operation, reducing tool downtime.

- Application Example: Used in EUV lithography chambers where thermal stability is non-negotiable.

3. Superior Barrier Against Copper Diffusion

- The Copper Challenge: Copper (Cu) interconnects in chips can diffuse into silicon substrates, causing short circuits.

- Tantalum’s Role:

- Barrier Layer: Forms a 2–5 nm Ta or TaN layer that blocks Cu diffusion, ensuring signal integrity.

- Adhesion Promoter: Enhances bonding between Cu and dielectric layers, critical for multi-level interconnects.

- Advanced Nodes: Essential for 3nm/2nm FinFET and GAA (Gate-All-Around) transistors.

4. Nanoscale Uniformity and Precision

- Film Thickness: Achieves ultra-thin, consistent coatings down to 5 nm, enabling:

- Miniaturization: Supports shrinking transistor sizes in logic and memory chips (e.g., TSMC’s N3E, Samsung’s SF3).

- Performance Consistency: Uniform films reduce resistance and leakage in AI/GPU circuits.

- Crystal Structure Control: Grain size <50 μm ensures smooth sputtering and minimal defects.

5. Extended Operational Lifespan

- Durability: Resists erosion from high-energy plasma, lasting 30–50% longer than tungsten targets.

- Cost Efficiency:

- Reduces target replacement frequency and maintenance costs.

- Lowers cost-per-wafer in high-volume fabs (e.g., Intel, SK Hynix).

- Case Study: A leading foundry reported a 20% reduction in downtime after switching to tantalum targets.

6. Sustainability and Recyclability

- Closed-Loop Recycling: Up to 95% of tantalum scrap from used targets can be reclaimed and reprocessed.

- Environmental Impact:

- Reduces reliance on mining conflict minerals (compliant with Dodd-Frank Act and OECD guidelines).

- Lowers carbon footprint in chip production.

- Industry Trend: Companies like Applied Materials and Umicore now offer tantalum recycling programs.

Emerging Applications

- Quantum Computing: Tantalum’s superconducting properties (critical temperature: 4.48 K) make it ideal for qubit interconnects in quantum chips (e.g., IBM Quantum).

- AI Hardware: Enables low-resistance interconnects in NVIDIA’s H100 GPUs and Cerebras’ wafer-scale engines.

- Space Electronics: Radiation-resistant tantalum films are used in satellites and Mars rovers.

Technical Challenges and Innovations

- Stress Management: Advanced annealing techniques mitigate film stress in 3D NAND stacks.

- AI-Driven Optimization: Machine learning models predict optimal target grain structures for specific chip designs, slashing R&D time.

- Hybrid Targets: Tantalum-ruthenium (Ta-Ru) composites improve adhesion in advanced EUV layers.

Why Tantalum Targets Are Irreplaceable:

From enabling Moore’s Law to powering AI and quantum leaps, tantalum targets are the silent enablers of technological progress. As chips shrink and complexity grows, their role will only become more pivotal.

Engineers: How are you leveraging tantalum in your designs? Facing challenges in film uniformity or sustainability? Share your insights!

Semiconductor #ChipManufacturing #AdvancedMaterials #SustainableTech

Key Takeaways:

- Combines technical depth (purity specs, process details) with real-world examples (TSMC, NVIDIA, quantum computing).

- Highlights sustainability and cost efficiency for ESG-conscious audiences.

- Encourages industry dialogue on evolving challenges and innovations.

Perfect for engaging both technical professionals on LinkedIn and tech enthusiasts on Facebook! 🚀